About Us

Galaxy's Profile

Galaxy Fire Protection Co. has started its journey in the year 2011 and it has reached height to become an Indian Fame Company in Fire Door Industries under the guidance of MR. AVNEESH KUMAR a well-known industrialist in the Fire Door Manufacturing Industries.

GALAXY, a name that has reached levels of excellence through of superior technology as a brand GALAXY has been tested and trusted by the country’s leading architects, corporate houses, multinational companies, Banks, Government organizations and Even PSU Unit.

Now We are Manufacturing full range in FIRE DOOR Solutions. Our experimentation has enabled our clients to add a touch of elegance in their conventional practice of having doors.

Our Mission

Our mission is to produce and continually develop quality products at a competitive price while fostering a climate where environmental technologies can thrive.

Our Vision

Our Vision is to introduce best quality products and services that enrich customer experiences in the residential, Industrial, commercial and Government /PSU’s

We will strive to be the best in every aspect of our business by utilizing our core competencies, fostering a culture of trust, teamwork and responsibility.

All the products are marketed in the brand name of GALAXY.

“GALAXY FIRE DOOR PROTECTION.”

With unwavering dedication to innovation and customer satisfaction, GALAXY has earned a reputation for excellence. Trusted by leading architects, corporations, multinational companies, international banks, government organizations, and PSU units, We ensures unparalleled fire safety. Our comprehensive range provides total fire door solutions, combining functionality with elegant design. Elevate your security standards and experience the art of protection with GALAXY.

Our Machineries

CNC Press Brake Machine

Multiple Thickness Planer

N.C. Shearing Machine

Air Compressor

Metal Surface Grinder

Rotary Drill Machine

Power Hammer Drill Machine (bosch)

Welding Machine Transformer Type

Metal Working Machine (verious)

Drill/Tapping Machine

Tapping Machine

Power Tools Including Circular Cutter

Hydraulic Punch Press

Welding Machine Mig

Planners, Grinder, Drill, Saws, Etc.

Circular Saw Cutter

Steel Section Circular Cutting Machine

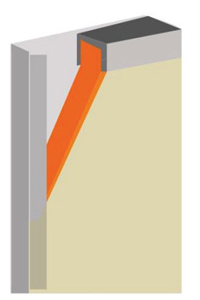

Door Leaf Construction

Honeycomb Core

Honeycomb Core is a perfect hexagonal shaped strong and lightweight core or filling material, made of 100% recycled paper. It is widely used as core infill Fire Rated material with various components.

- 100% recycled paper

- High pressure strength.

- Qualified as a core material between flat and moulded facings.

- Easily adapts to any shape.

- Outstanding deformation properties.

Rockwool with Stiffener

The high density Rockwool board insulation produced from molten basalt rocks spun to fine fibers and bonded with heat resistant binder.

- Rockwool infill is used in the steel stiffened doors.

The rockwool infill board meets the requirements of the technical standard ASTM C-612. - Steel stiffed door has vertical steel- stiffeners

throughout the height of the door. The cavities between two stiffeners are filled with mineral rockwool. - The combination of optimized density, fibre direction and excellent fit of mineral rockwool provides ideal thermal and acoustic insulation for steel doors.

Polyurethane Core

This insulated core is a foam that is injected into the core and expands to fill all the available space within the cavity of the hollow metal door.

- Polyurethane will have the best insulation value. However, a polyurethane door cannot be fire rated. This insulated door generally user for clean room type of environment.

- Lead line Core: Lead-lined cores must have a lead thickness specified and are used to restrict harmful X-rays from passing through the door.